DFIT-FBA Background and Field Example

Background

Closure pressure (a proxy for minimum in-situ stress), reservoir permeability, and reservoir pressure estimates are critical to hydraulic fracture stimulation design for multi-fractured horizontal wells (MFHWs). Diagnostic fracture injection tests (DFITs) have become the standard pre-stimulation method for obtaining these properties.

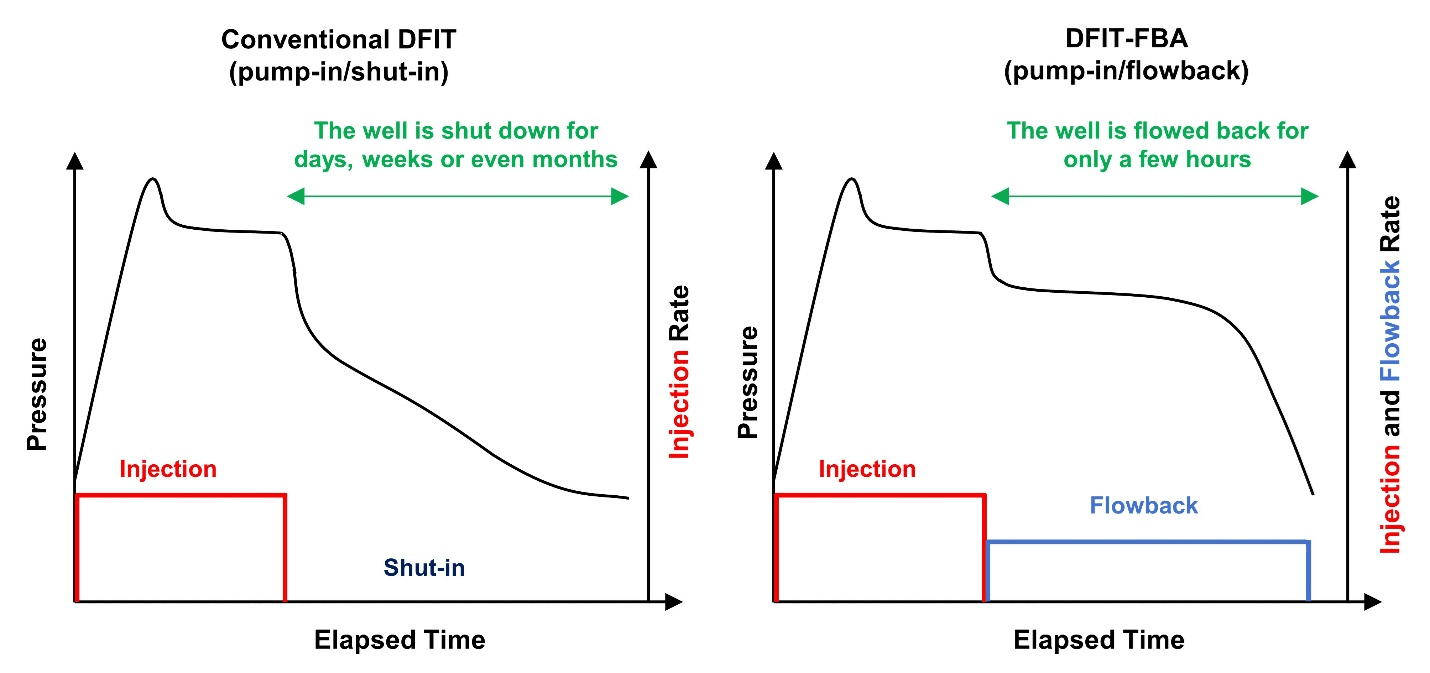

The procedure used for a conventional DFIT, as applied to MFHWs, involves high-pressure water injection into the 'toe' of the horizontal well to initiate and propagate a small fracture, followed by shutdown of the pump and monitoring of pressure decline over time (Fig. 1, left). The pressure falloff data can be analyzed to obtain instantaneous shut-in pressure (ISIP), closure pressure, reservoir pressure and reservoir permeability. The main drawback of the conventional DFITs is that, for low-/ultra-low permeability reservoirs, the shut-in time required to obtain reservoir data (e.g., reservoir pressure and permeability) can be very long (days, weeks, or even months).

An alternative approach to DFIT design is to flowback the injected fluid immediately after the pump is shut down (Nolte, 1979; Nolte and Smith, 1981). Historically this approach has been used to accelerate fracture closure (for closure pressure) only. The procedure used for a conventional flowback DFIT, after the pump-in cycle and propagation of the mini-fracture, is to flowback the well through a surface choke and analyze the flowing pressure data to estimate closure pressure. The main drawback of this approach is related to flowback rates; historically, because the tests were designed to accelerate closure, relatively high flowback rates were used, causing a loss of connectivity with the reservoir. As a result, reservoir information generally cannot be obtained from the conventional (pump-in/flowback) flowback DFIT.

To address these issues with both the conventional DFIT (time required to obtain reservoir information), and the conventional flowback DFIT (loss of reservoir information), TOC researchers re-designed the flowback DFIT. This new DFIT procedure, referred to as DFIT-FBA (where FBA = flowback analysis, Fig. 1, right), involves flowing back the well at a relatively low rate (2-5 % of injection rate) to not only accelerate closure but also to maintain wellbore-reservoir connection, allowing estimation of reservoir permeability and reservoir pressure in just a few hours (Zanganeh et al., 2020; Zeinabady et al., 2022a and 2022b). The flowback rate and pressure data associated with the flowback portion of the test is analyzed using rate-transient analysis methods (RTA, Clarkson, 2021) to obtain these properties (hence the‘FBA’ in the name).

Figure 1. Conceptual diagrams comparing conventional (pump-in/shut-in) DFIT (left) with DFIT-FBA (right). Images courtesy of Dr. Danial Zeinabady.

Field Example

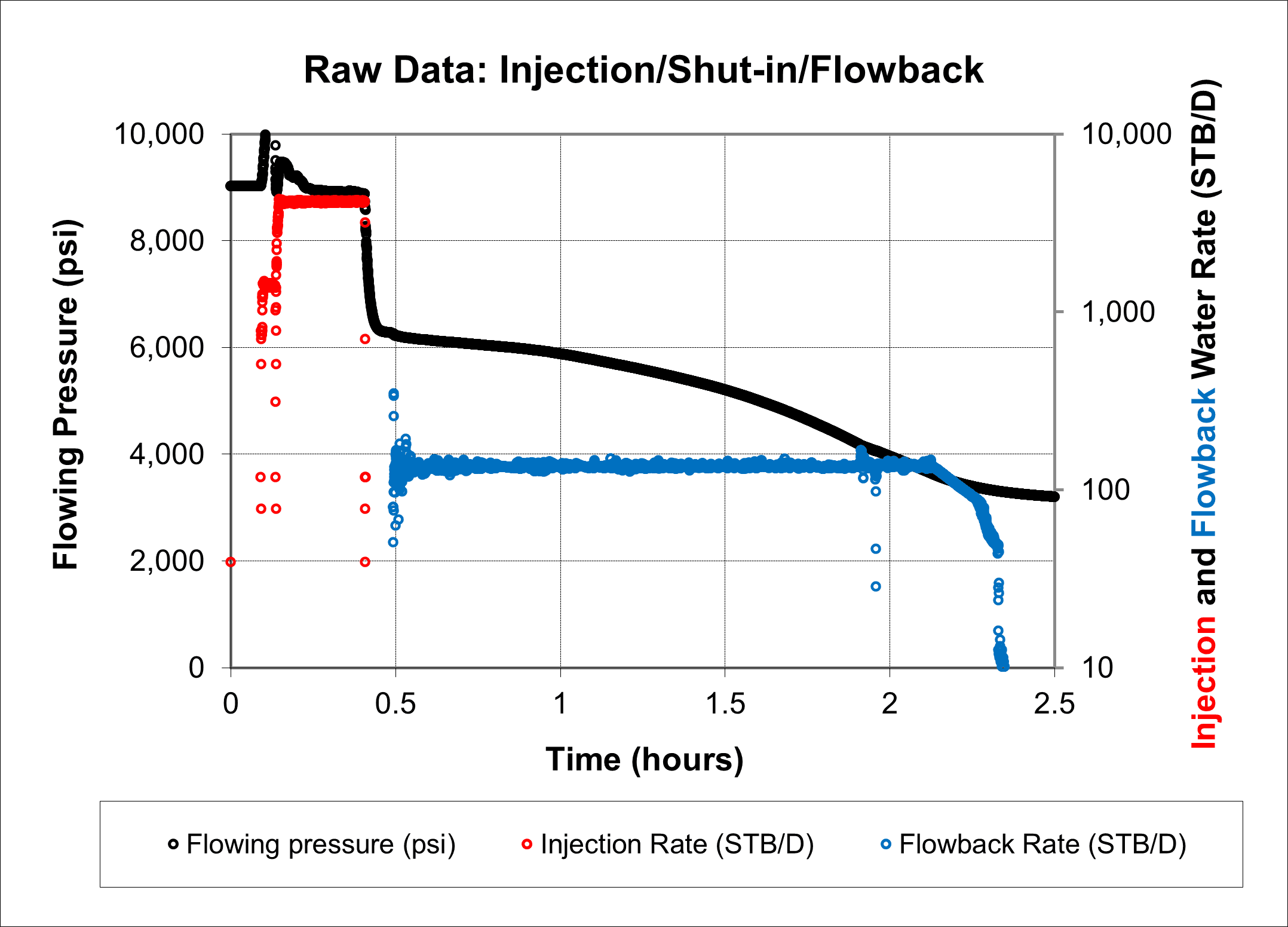

The following field example corresponds to a DFIT-FBA test performed at the toe of a cased and cemented horizontal well completed in a low-permeability reservoir in the Montney Formation (Fig. 2). Pressure data were collected at the surface and converted to bottomhole by adding hydrostatic pressure. Water was injected at a surface rate of approximately 4176 STB/D (2.9 STB/min). The injection period lasted for 16 minutes, and a total volume of 46.2 STB was injected. There was a short shut-in period after the injection period and before initiating flowback operations. The well was flowed back at an approximately constant surface rate of 135.4 STB/D for about 112 minutes.

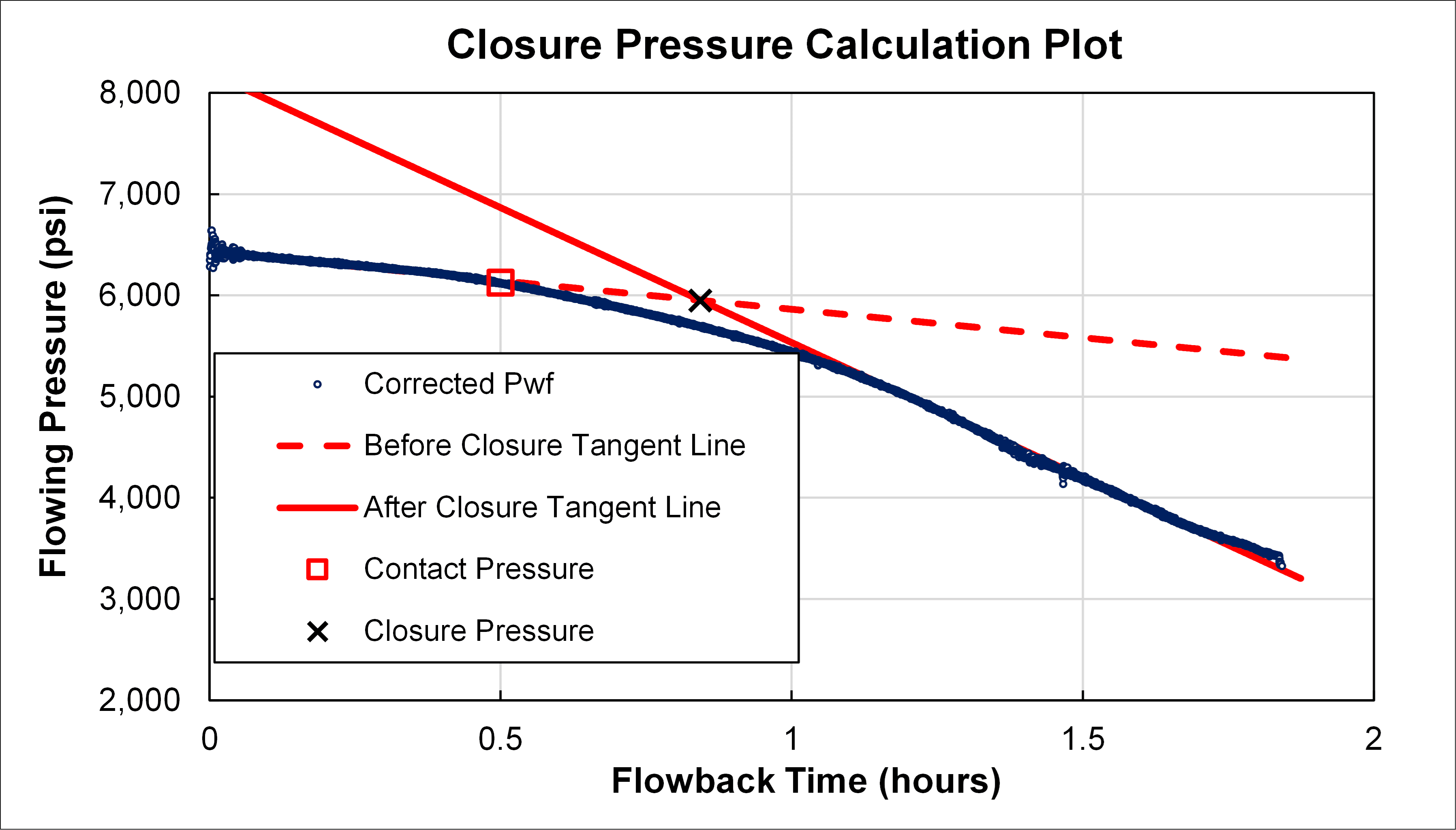

A Cartesian plot of (corrected – for near-wellbore friction) flowing pressure versus flowback time was used (Fig. 3) to estimate closure pressure (and hence minimum in-situ stress) using the tangent line method (Plahn, 1997).

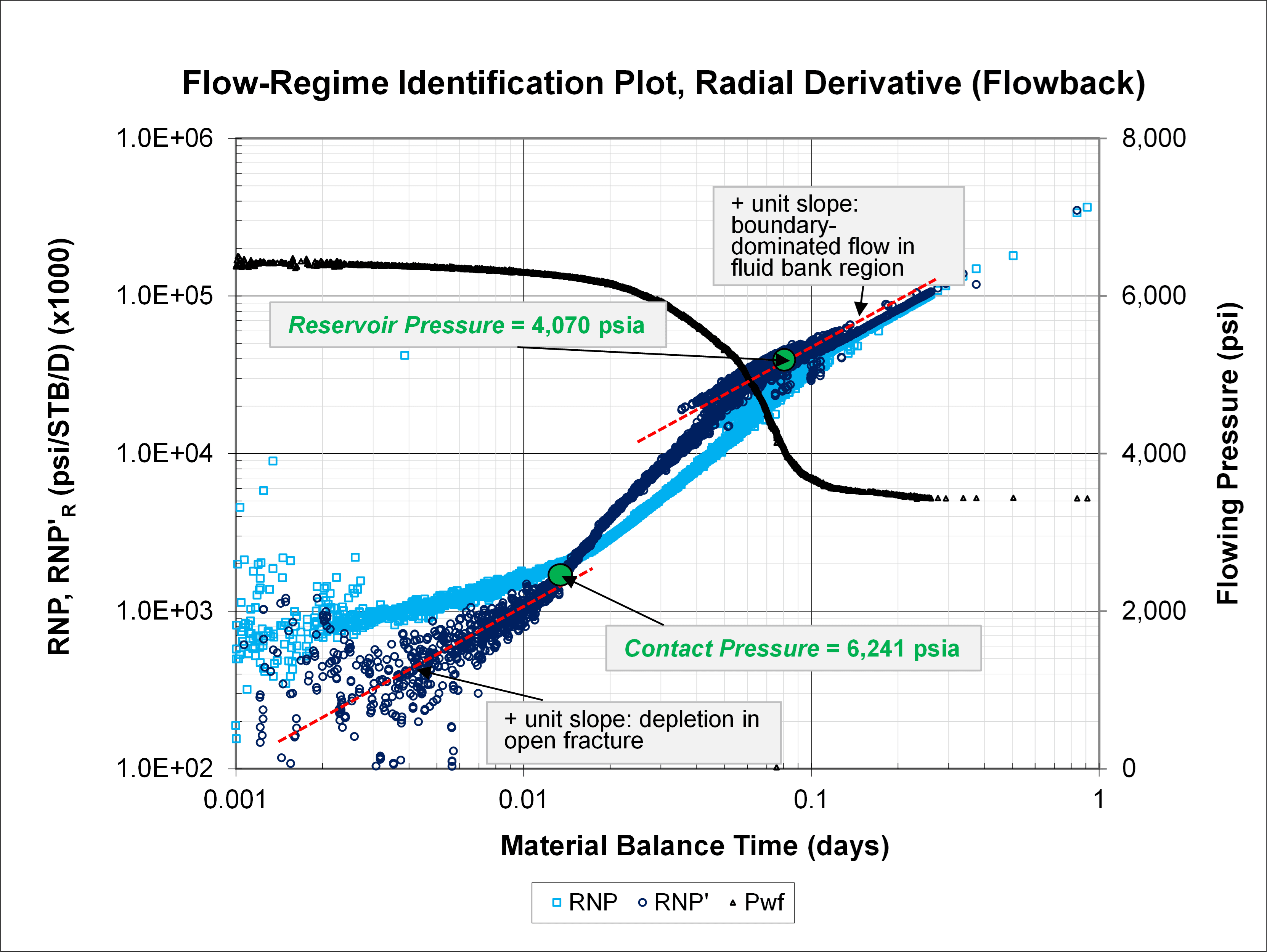

A log-log plot of rate-normalized pressure, and its derivative with respect to the natural logarithm of material balance time, was used to identify flow regimes during the flowback period (Fig. 4). This is one of the most important steps in rate-transient analysis (Clarkson, 2021). The observed flow regimes are before-closure fracture depletion (first unit slope on the plot) and after-closure fluid bank depletion (second unit slope on the plot). Following the procedures outlined by Zeinabadybejestani (2023), permeability, fracture area, and open fracture stiffness were estimated using a straight-line analysis RTA technique applied to the data associated with fracture depletion (first unit slope on the plot), contact pressure was estimated from the end of the first unit slope, and reservoir pressure was obtained from the start of second unit slope line (corresponding to fluid bank depletion). In some cases, if post-flowback shut-in (rebound) data is collected, and after-closure linear flow is identified, another estimate of reservoir pressure may be obtained from impulse linear flow analysis (not observed in this case).

Figure 2. Raw data (rates and pressures) for studied DFIT-FBA performed in the Montney Formation.

Figure 3. Cartesian plot used to estimate contact and closure pressure.

Figure 4. Flow-regime analysis plot used to obtain estimates of contact and reservoir pressure. The data associated with the first unit slope line (fracture depletion) is used to obtain permeability from a straight-line analysis RTA method (Zeinabady et al., 2022b).

Summary

Table 1 summarizes the estimated parameters. This test was completed in just over 2 hours, while a conventional DFIT usually takes 2 weeks to be completed in this reservoir (Zeinabadybejestani, 2023).

| Parameter | Value |

|---|---|

| Minimum in-situ stress, psi | 5951 |

| Contact Pressure, psi | 6241 |

| Reservoir Pressure, psi | 4070 |

| Open fracture stiffness, psi/ft | 111,049 |

| Fracture surface area, ft² | 6235 |

| Reservoir permeability, md | 2E-04 |

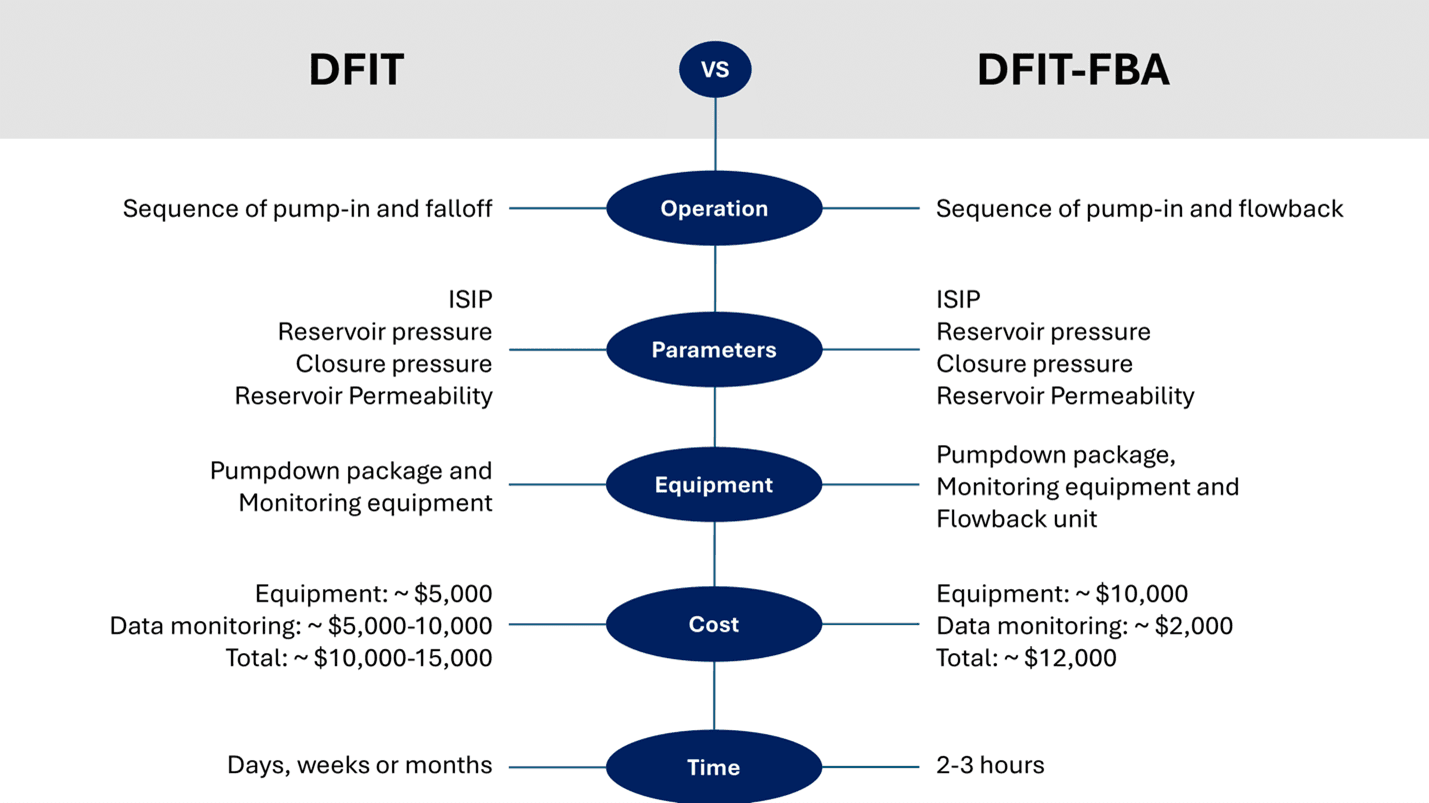

This example demonstrates that DFIT-FBA can be used to obtain all the same information as a conventional DFIT, but in a fraction of the time. Additional comparisons (operation, parameters, equipment, cost, time) between the two DFIT types are provided in Fig. 5.

Figure 5. Comparison of a conventional (pump-in/shut-in) DFIT with DFIT-FBA. Image and information courtesy of Dr. Danial Zeinabady.

References

Clarkson, C.R. 2021. Unconventional Reservoir Rate-Transient Analysis, 1117p. Houston, Texas, USA: Gulf Professional Publishing.

Nolte, K.G. 1979. Determination of Fracture Parameters from Fracturing Pressure Decline. Presented at the SPE Annual Technical Conference and Exhibition, Las Vegas, Nevada, 23- 26 September. SPE-8341-MS.

http://dx.doi.org/10.2118/8341-MS.Nolte, K.G., and Smith, M.B., 1981. Interpretation of Fracturing Pressures. Journal of Petroleum Technology 33(9):1767-1775.

https://doi.org/10.2118/8297-PA.Plahn, S.V., Nolte, K.G., and Miska, S. 1997. A Quantitative Investigation of the Fracture PumpIn/Flowback Test. SPE Production and Facilities 12(1):20-27. SPE-30504-PA.

https://doi.org/10.2118/30504-PA.Zanganeh, B., Clarkson, C. R., Yuan, B. et al. 2020. Field Trial of a Modified DFIT (Pump-in/Flowback) Designed to Accelerate Estimates of Closure Pressure, Reservoir Pressure and Well Productivity Index. J Nat Gas Sci Eng 78.

https://doi.org/10.1016/j.jngse.2020.103265.Zeinabadybejestani, D. 2023. Advancing Design and Analysis of the Diagnostic Fracture Injection Test-Flowback Analysis ('DFIT-FBA')Method and Post-Fracture Pressure Decay (PFPD) Technique. University of Calgary, Calgary, AB, Canada.

https://dx.doi.org/10.11575/PRISM/dspace/41400.Zeinabady, D., Clarkson, C. R., Zanganeh, B., and Shahamat, S. 2022a. First-Time Implementation of the Flowback DFIT (“DFIT-FBA”) at Multiple Points along a Horizontal Well. J Nat Gas Sci Eng 102.

https://doi.org/10.1016/j.jngse.2022.104601.Zeinabady, D., Clarkson, C. R., Tabasinejad, F. et al. 2022b. Estimating Reservoir Permeability and Fracture Surface Area Using the Flowback DFIT (DFIT-FBA). SPE Res Eval & Eng 25 (4): 704–718. SPE-210560-PA.

https://doi.org/10.2118/210560-PA.